Flanges Class 150 5″ in Kenya, Uganda, Tanzania, Ethiopia, Juba & Rwanda – System Star Technologies Limited

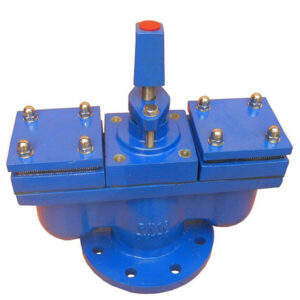

System Star Technologies Limited supplies Flanges Class 150 5″, engineered for secure and leak-proof connections in industrial, chemical, and fluid piping systems. Moreover, these flanges are manufactured from high-quality carbon steel or stainless steel, providing durability, corrosion resistance, and reliable performance under standard Class 150 pressure ratings.

Furthermore, they are suitable for steam, water, chemical, and fluid pipelines across Kenya, Uganda, Tanzania, Ethiopia, Juba, and Rwanda. These flanges ensure long-lasting joint integrity and maintain sealing efficiency for both maintenance and new piping installations.

Applications of Flanges Class 150 5″

| Industry | Application |

|---|---|

| Chemical Processing | Safe joining of chemical and corrosive pipelines |

| Water & Wastewater | Leak-proof connections in distribution and treatment systems |

| Petrochemical & Refinery | High-pressure piping and equipment connections |

| Steam & Heating Systems | Secure sealing in high-temperature steam lines |

| Industrial Maintenance | Replacement of worn or damaged flanged joints |

Key Features & Benefits

-

Firstly, Class 150 pressure rating – Ensures safe operation under standard industrial pressures

-

Moreover, durable construction – Provides long-lasting corrosion and wear resistance

-

Additionally, precision-machined surfaces – Guarantees tight, accurate, and leak-free flanged connections

-

Furthermore, standard 5″ size – Compatible with medium to large-diameter piping systems

-

Finally, versatile use – Suitable for chemical, fluid, steam, and water pipelines

Technical Data Sheet

| Parameter | Typical Value |

|---|---|

| Product Name | Flange Class 150 5″ |

| Material | Carbon steel / Stainless steel (as required) |

| Size | 5 inches |

| Pressure Rating | Class 150 |

| Connection Type | Flanged joint |

| Application | Industrial, chemical, and fluid piping systems |

| Temperature Range | Standard industrial conditions |

| Packaging | Individual or bulk |

| Supplier | System Star Technologies Limited |

| Coverage | Kenya, Uganda, Tanzania, Ethiopia, Juba, Rwanda |

Why Choose System Star Technologies Limited

System Star Technologies Limited offers high-quality Flanges Class 150 5″ with reliable performance and long service life. We provide bulk and single-item supply options with fast delivery across East Africa. Moreover, our flanges are suitable for industrial, chemical, steam, and water piping systems, making us a trusted supplier for both maintenance and new installations.

FAQs – Flanges Class 150 5″

-

What are Flanges Class 150 5″ used for?

They connect medium to large-diameter pipes and equipment under standard Class 150 industrial pressures. -

Are these flanges suitable for chemical and steam pipelines?

Yes, they perform reliably in chemical, fluid, and steam applications. -

Can they withstand high pressure and temperature variations?

Yes, Class 150 flanges maintain sealing integrity under standard industrial conditions. -

Do you supply bulk quantities?

Yes, both bulk and individual pieces are available. -

How can I place an order?

Contact System Star Technologies Limited directly.

Contact Us

📍 Address: KCB Building, Enterprise Road, Industrial Area, Nairobi, Kenya

📞 Phone: +254 726 086 895

📧 Email: systemstartechnologies@gmail.com

💬 Order Now – Partner with System Star Technologies Limited, your reliable source for premium industrial products in East Africa.

Reviews

There are no reviews yet.